Bec Ashford, Print & Fabric Technician

“My role as Print and Fabric Technician at David Nieper is an important link between design and production and ensures we are using our printers to their full potential in order to achieve a high quality in our designs and colours. One of the main focuses of the role is to create an achievable colour gamut for each fabric base that we print in house. This allows designs to be easily changeable and means the colour is much easier to control.

Aside from the colour profiling, I work alongside our Print Designer to prepare designs for production as well as running the printer from time to time and admin tasks such as calculating the ink cost.

Being able to say that the garments produced here are handmade in Derbyshire is a brilliant achievement, as is the efforts made in becoming a sustainable fashion brand. Being part of that is something to be proud of.

I studied Textiles at University and have always enjoyed being creative. Print and Surface Design has always been a passion of mine. Seeing and being involved in part of the many processes that go into producing a garment is really interesting. The textile and fashion industry is always changing and developing which keeps the job exciting.

I’ve learnt a great deal already at David Nieper. The role here has not only broadened my fabric and textile knowledge but I’ve learnt a lot about the machinery and processes involved in manufacturing printed fabrics for garments on a large scale. I’ve built upon my CAD experience by being here and have had the opportunity to learn with new design software.

There are many challenges in this job, not just because of the nature of the industry, but mostly because this part of the company is so new. The role is constantly being built upon as the production team learn and adapt to the needs of the business. As a team we work really well in solving any of the issues we are faced with in the printing department.”

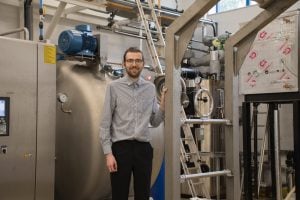

Ben Poole, Dye Specialist

“My Role at David Nieper is Dye Specialist which involves dyeing the Fabrics for use in the garments that we produce as well as helping with the production of the printed fabrics. My role is important because if I don’t get the fabrics dyed correctly and at the right time there will be a delay on the garments that need to be made from those fabrics.

“My Role at David Nieper is Dye Specialist which involves dyeing the Fabrics for use in the garments that we produce as well as helping with the production of the printed fabrics. My role is important because if I don’t get the fabrics dyed correctly and at the right time there will be a delay on the garments that need to be made from those fabrics.

I like working at David Nieper because it’s a good working environment and I feel valued as a member of the team. The good thing about working in textiles is getting a sense of satisfaction when you see someone wearing something that you had an involvement in making.

Since beginning working at David Nieper I have learned a huge amount about digital printing of fabrics and the associated processes. We have set up this unit from scratch and when we come across problems we solve them as a team.”

Dale Warriner, Fabric Print

“My role at David Nieper is Fabric Print Operator and I run the machines that get the fabric ready for its next process. My role is important for the business because we get all of the printed fabric ready and it is the first point of making the garments.

“My role at David Nieper is Fabric Print Operator and I run the machines that get the fabric ready for its next process. My role is important for the business because we get all of the printed fabric ready and it is the first point of making the garments.

I enjoy the environment and learning new experiences each day as I have never worked in a textile environment before. I enjoy the challenge of making prints ready for the next process.

I have learnt a lot since I started working at David Nieper and believe my knowledge can be increased more within the textile industry. We pride ourselves on producing very high quality printed fabric, at speed.

There are many challenges that can happen when making prints and I can now help to solve most problems with the training and knowledge I have gained so far.”

Joanne Murray, Fabric Cutting

“Within the Cutting Department I run the cutter – this machine cuts out the garments into the different sections – i.e., fronts, backs, sleeves etc. I also carry out re-cuts on the fabric – this is the hand cutting of garments which have been sent back from sewing due to faults and complete wash tests to ensure the stability of the fabric. I enjoy being able to see the garment through from start to finish – knowing the process from cutting out the garment shapes through to the end product.

“Within the Cutting Department I run the cutter – this machine cuts out the garments into the different sections – i.e., fronts, backs, sleeves etc. I also carry out re-cuts on the fabric – this is the hand cutting of garments which have been sent back from sewing due to faults and complete wash tests to ensure the stability of the fabric. I enjoy being able to see the garment through from start to finish – knowing the process from cutting out the garment shapes through to the end product.

Since working in Cutting, I have learnt all about the full process of garment making – from examining fabric, hand laying, how to use the cutter, cutting fusing blocks, hand lay and mosaic cutting. I have also learnt to help with machine breakdowns as I now know when blades or belts need changing. There is still so much to learn which makes my job interesting and I can’t wait to learn more.

There are many opportunities to work in different departments within the company – when I first joined the company I started working in the David Nieper Café and I then progressed into my current role in the Cutting Department.

David Nieper is a fantastic work place; lovely, friendly people work here and here in Cutting we have an excellent team that works really well together. It is a family orientated business where you always get help – whether work related or personal.”